Related Articles

Understanding Bill of Materials In Odoo. When using an ERP system, master data management often becomes an obstacle for the companies. One of the most important parts of ERP master data are Bills of Material, BOMs. In this article, we’re going to explain how to use and manage them successfully.

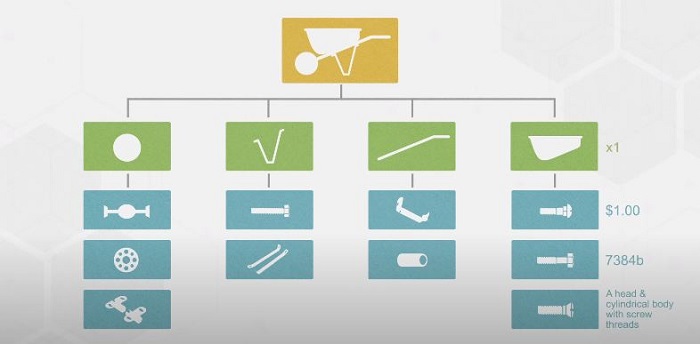

A BOM consists of all the parts used to build your product separated into different levels. The final product that gets to the customer is Level 0, while level 1 can be one or more subassemblies used in level 1. You can have as many levels as possible, but for the sake of simplicity, it’s better to have just a few.

A BOM level includes a list of part numbers and the quantity of each of them required to make up the next level. Such things like part descriptions and units of measure are often mistakenly considered to be parts of a BOM too, but they are in fact items in the part master file, not the ERP master data item. Of course, these aspects are crucial for your system too.

First off, let’s define and understand what a Bill of Materials is in order for us to be able to see just how Odoo ERP can help you stay on top of your production process – so that you can focus on working at the business, instead of working in the business.

Bill of Materials (BOM)

To understanding Bill of Materials in Odoo, You have to know what is Bill of Materials first. A bill of materials is a definition that is used for a list of all the parts, items, and materials that are essential to the creation of your product. Usually, a BOM also has an instruction on how the parts and materials should be used and handled. A BOM is like a recipe for a dish, so it’s extremely important to follow it to make sure every step and component is taken care of.

Now that we have a better understanding of what the concept of a Bill of Materials is and just how crucial it is to your business especially if you are in the manufacturing industry, let’s see how Odoo can help you manage and use them in an efficient manner that will streamline process and reduce waste in the process.

Setting Up a BOM on Odoo

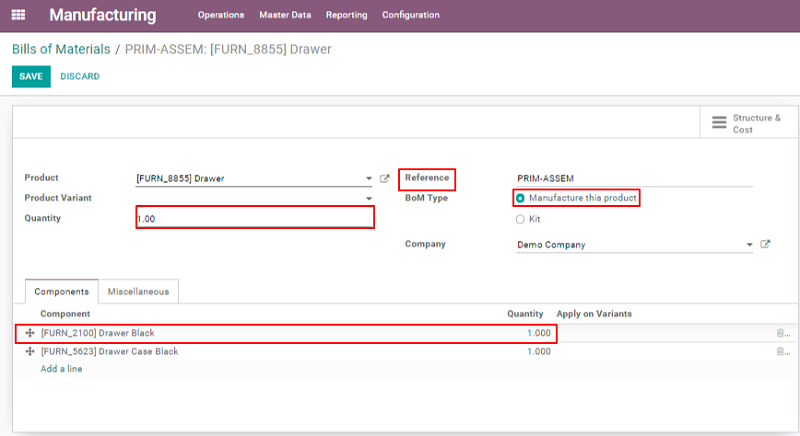

This is The first thing to understanding Bill of Materials In Odoo. A BOM includes the descriptions of component products, the required quantity of each of them, and a detailed description of the manufacturing process with all the routing and steps. In Odoo, a product can have several BOMs associated with it, even though a BOM can only be associated with one product. At the same time, one BOM can describe many variations of one product.

How to Set up a Basic BoM

If you opt for manufacturing operation management through manufacturing orders only, your BOM will be defined without routings.

The first step to understanding Bill of Materials In Odoo is Start with creating at least one product and one component. There are two ways to do it: from Master Data ‣ Products or on the fly from the BOM form. To find out more information about configuring products, refer to the Inventory chapter. When you have created a product and a component, click on them on the dropdown menu to add them to your OoM. To create a new bill of materials, choose Master Data ‣ Bills of Materials or click on the button on top of the product form. The Miscellaneous tab will give you a chance to fill additional fields. Sequence is the order in which your BOMs will be selected for the production order, starting with lower numbers. With Version, you can track changes to your BOM.

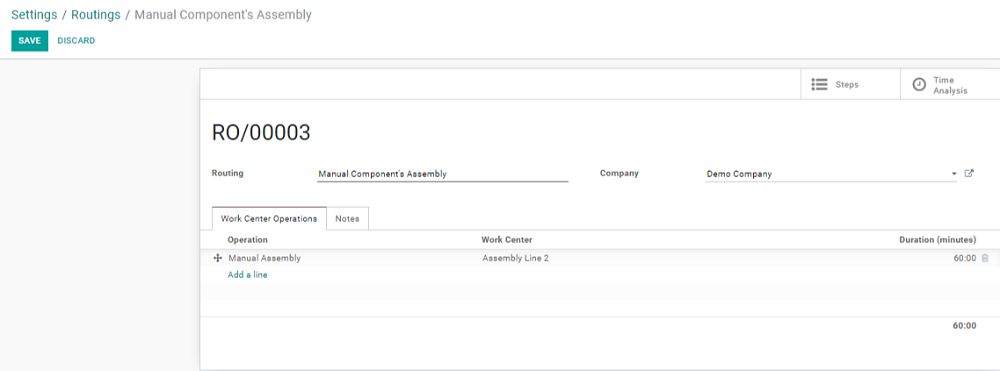

How to Add a Routing to a BOM

Routing describes the essential manufacturing operations and the work centers at which the operations will be performed. Although a BOM can’t have more than one routing, one routing can be added to several BOMs.

First, enable routings from Configuration ‣ Settings. Then you can add routing to your BOM by choosing one from the dropdown list or creating one on the fly. For you to be able to define or set up a work operation or otherwise a step wherein each component is going to be consumed, you may use a field through the Consumed in Operation option under the Components tab. You can also define the operation wherein the product is going to be produced just right under the Miscellaneous tab with the Produced at Operation field. If you would like your products to be consumed or produced at the final operation in the routing, leave that field blank. That is the next step to understanding Bill of Materials In Odoo.

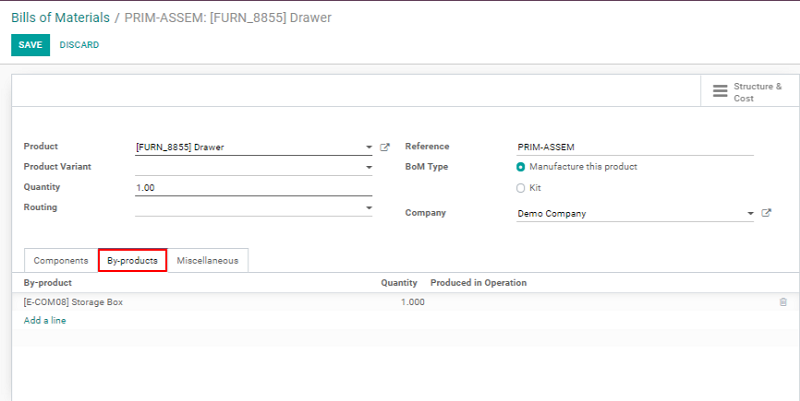

Add Byproducts to a BOM

Any BOM product that was produced in addition to the primary products is considered a byproduct in Odoo. To add one to your BOM, enable them in the Configuration ‣ Settings section. Once you do so, you will be able to add bills of materials under the Byproducts tab. Any product can be added as a byproduct. They are produced at the same stage of the routing as the primary products.

Set up a BOM for a Product With Sub-Assemblies

A manufactured product that is meant to be used as a component of another manufactured product is a subassembly. Subassemblies are great for simplifying a complex BOM and an accurate representation of your manufacturing flow. Bills of materials that use subassemblies are often called multi-level BOMs.

Multi-level BOMs in Odoo are created by, for instance, a BOM at the top level as well as corresponding BOMs on the subassembly. Then you next have to set the route of procurement for the product on the subassembly. This way, each time you create a manufacturing order for the top-level product, a manufacturing order for the subassemblies will be created too. Is that enough to understanding Bill of Materials In Odoo?

Top-Level Product BOM Configuration

In order to configure a multi-level bill of materials, create the top-level product and the BOM for it and include the subassemblies in the list of components. Then create a BOM for every subassembly just how you’d do it for a product.

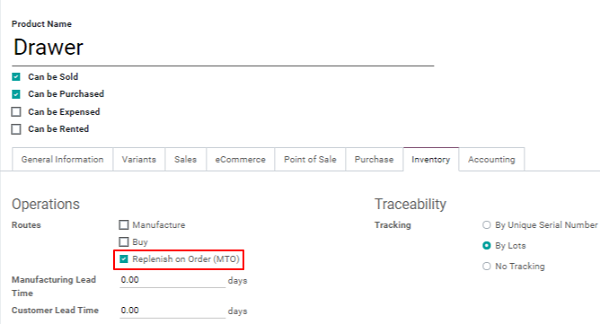

Subassembly Product Data Configuration

Start by choosing the Manufacture and Make To Order on the subassembly’s product form. The Manufacture route will outweigh the Buy route, so make sure not to select it.

You can also purchase the subassembly besides manufacturing it by selecting Can be Purchased. You can configure all the other fields on the product form according to your liking.

Use a Single BoM to Describe Multiple Variants of a Single Product

With Odoo you can use one BOM for several variations of one product. To enable it, go to Configuration ‣ Settings. Afterward, specify which component lines are needed for the manufacture of each variation. You can specify several variants for each line, but if the variant is not specified, the line will be used for all of them.

If you’re defining variant BOMs on a line-item basis, leave the Product Variant field in the main section of the BOM blank. Use this field only if you want to create a BOM for one variant of a product. Start your business after understanding Bill of Materials in Odoo.

Conclusion

Understanding Bill of Materials In Odoo helps us to increase our business. Nowadays, most of the ERP systems allow you to use configurable BOMs. They combine existing parts and subassemblies as an order is entered into the exact configuration your customer prefers. Since this exact combination can never be duplicated, engineering controls don’t have to manage a one-time order configuration.

Besides, you can use your BOM for material planning. You can make a planning BOM and master schedule that allows parents to force purchases of certain components through your forecast. Usually, a BOM will have percentages for each component instead of units, but they will not necessarily add up to 100%.

BOM is an essential part of your quality and control systems. If you manage your BOM through your ERP system, you will improve inventory flow, material planning, and will bring strategic benefits to your business. That’s why it’s crucial that you invest enough time into learning how to manage it.

With Odoo ERP, you can edit and manage your imported BOM with ease and add layers of detail, so it makes managing complex types of BOMs much easier. Since your BOM is housed within your ERP, make sure everyone is working with its most recent version.

Finally, using an ERP to create and manage your BOM simplifies the procurement of parts. While you’re still in the process of designing and engineering your product, the procurement team can already access the EBOM to decide which long-lead items are missing and order them straight away, so that you have all the necessary parts when the production begins. Of course, the purchasing department will always know what is missing since the system is automatically connected to your inventory. What will you do after understanding Bill of Materials in Odoo?

Are you a small to medium-sized company engaged in manufacturing or similar industries wanting to see what enterprise resource planning systems can do for your organization and improve its processes and operations to be more productive and efficient? Get in touch with Syncoria today!

Our expert consultants come from all segments of industry from all parts of the world, so we understand both the software and the unique needs of your business very extremely. Contact us today if you want to know more information as to how Odoo can benefit your organization – we’d love to be partners with you in achieving your business and organizational goals.