Related Articles

How Can Material Requirement Planning (MRP) Benefit A Manufacturing Company?

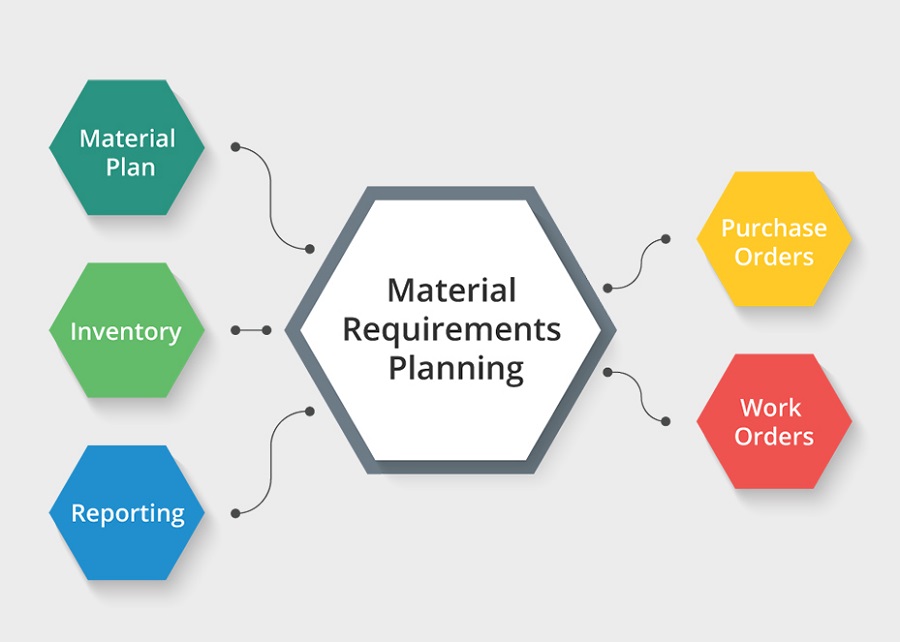

Material Requirement Planning (MRP) is a common term in the manufacturing industry, but what does it mean exactly?

In short, material requirement planning is a production planning and inventory management system designed to manage manufacturing business processes.

Its ultimate goal is to keep adequate inventory levels to ensure that the required materials are available as they are needed.

Material requirement planning is beneficial to manufacturing companies who use assembly lines or require multiple parts to create their products.

Many companies implement MRP software to track and organize their inventories, as well as to ensure that the required products and parts are in place when an order is made.

When implemented and maintained properly, material requirement planning will increase profitability, reduce cash flow and lead times, improve productivity, and give companies the ability to be proactive in their inventory management efforts.

In order to maximize the money brought in, companies need to establish a good balance between inventory and product demand.

Without the right balance, companies will incur unnecessary costs. Companies also need to ensure that materials are ordered at the right time in order to prevent production delays and missed deadlines.

Material requirement planning will assist manufacturing companies to plan out the production schedule and determine when materials need to be ordered for which products.

Key Challenges of MRP Systems

Poor inventory management

Close control over inventory is vital for profitability and efficiency.

Just-in-time (JIT) manufacturing has made good control processes even more important: if you don’t carry large stocks, you need to know what you have and be able to reorder it as and when needed.

But the benefits of effective inventory control extend beyond pure production efficiencies, and include aspects such as minimizing wastage and spending – both of which can impact on the bottom line.

Inadequate quality control

Customers have always had the ability to be unforgiving, but never more so than in today’s climate of instant feedback and social sharing.

In this climate manufacturers need to ensure that quality control is designed-in and built-in from start to finish.

Though this is not inherently easy to achieve, it’s essential to have systems capable of preempting or responding to manufacturing problems quickly and efficiently.

Supply chain problems

There was a time when manufacturers sourced almost everything they needed – whether raw materials or components – from local suppliers.

However, in the modern world it’s possible and often beneficial to source further afield, e.g. for lower cost.

There can, however, be multiple problems with this global supply chain including: price fluctuations, reliability issues and quality control among others.

Data management failures

Businesses generate masses of data, but all too often this invaluable resource is used ineffectively – or not at all.

Information about everything from raw-material pricing to supplier performance is now readily available.

The opportunity to gain insights from such data could, however, be wasted, and any benefits from these insights lost if the business has the ‘MRP issues’ of having limited or outdated IT systems.

Ineffective process management

As the saying has it, “constant change is here to stay” – and the pace of change now seems to increase every year.

The 21st century has many drivers for such change: these include the speed with which information is exchanged, the increasing generation of data, widening customer expectations, and the relative ease with which new products can be introduced into the market.

To cope with these factors, it’s essential for manufacturers to have clear control of their processes: without this, isolated ‘quick fixes’ to respond to changing demands can go on to cause costly manufacturing problems.

Choose The Right System

Odoo Manufacturing software is the modern solution to today’s MRP problems.

It does not require time clocking: Accurate planning directly based on real manufacturing times measures.

The software’s MRP, Quality, Maintenance and PLM are fully integrated. It allows Realtime Communication by displaying worksheets, quality alerts to workers during operations.

It also has shop floor automation system allowing you to capture data in real-time from your equipment using the API.

Optimize your inventory level

Through accurate fulfillment propositions, businesses can optimize their inventory level through the software.

You can use make-to-order rules, minimum stock rules or the master production schedule to automate procurements.

Let the scheduler compute everything for you. Use routes, constraints and lead time to optimize inventory level and avoid shortages.

Barcodes to Speed up Operations

Whether you use lots, serial numbers or unidentified products, you can use barcodes to speed up operations at every step: Reception control, Picking, Packing, Work orders, and more!

Great Reporting & KPIs

All the data you need will be at your fingertips. The software allows you to control your productivity with real-time Overall Equipment Efficiency (OEE) reports and monitor the 6 big losses of TPM, track maintenance KPIs like MTTR and MTBF, and create customized dashboards to monitor performance in real time.

Dynamic reports on everything from costing to traceability, performance analysis, OEE, and more help you make smarter decisions about your business.

Smart Work Center Control Panel Interface

A friendly and smart work center control panel interface of the software allows users to tract time, display worksheets, register production, integrate quality checks, record serial/lot number and give in process alerts.

Who Are We?

Syncoria is a digital transformation solution based in Canada. We have been providing business solutions all over the world for over 14 years.

Odoo is one of our ready partners who specialize in integrated business solutions.

MRP system is one of Odoo’s specialties. Odoo has over 3 million happy business owners all over the world.

Your inventory, CRM, accounting, HR and every other need is Odoo’s priority. Feel free to consult Odoo for any business related questions and estimates.