Related Articles

Keep up good inventory levels. The part of the supply chain that is mainly concerned with consistently having the correct items in the correct amount available to be purchased, at the perfect time is called inventory management.

Once this is done correctly, organizations decrease the expenses of conveying abundance stock while expanding the business. A sound inventory management strategy can enable you to follow your stock progressively to streamline this procedure.

By adequately taking care of your stock you can have the correct items in the correct amount close by and maintain and keep yourself from ending up with items being out of stock and assets being tied up in excess stock.

You can likewise guarantee your items are sold so as to keep them away from wear or going out of date, or spending an excessive amount of cash on stock that is occupying room in a distribution center or warehouse.

Tips to keep up good inventory levels

A good inventory management strategy is key for guaranteeing a business has sufficient stock on hand in order to satisfy client needs.

In the event that it is not given adequate attention, it can bring about a business either losing a significant amount of cash on potential business that cannot be filled, or squandering money by buying an excessive amount of stock. An effective inventory management framework can likewise enable you to anticipate various (and some common), kinds of missteps.

Here are a few tips to help keep your inventory on optimum levels.

Set par levels

Make inventory management easier by setting “par levels” for each of your products. Par levels are the minimum amount of product that must be on hand at all times. When your inventory stock dips below the predetermined levels, you know it’s time to order more.

Par levels are varied based on the product in question and how long it takes to get it back in stock.

Even though initially setting par levels involves some amount of research and decision making (read: going with your gut), it will bring order to your orders (pun shamelessly intended) in the long run. This will not only make it easier for you to make decisions, but it will also allow your staff to make decisions for you.

Remember that in real life, the business environment is dynamic and conditions can gradually, or drastically change.

Make sure to perform routine checks several times throughout the year (every quarter for example), to ensure that your current par levels are still logical. You shouldn’t hesitate to adjust your par levels if there are changes in the meantime.

A simple formula for determining a good reorder point is given below:

Reorder point = (Lead time in days Average daily sales volume) + Safety stock

Note that this will only give you an estimate. The precise value of a reorder point will have to come from you.

First-In First-Out (FIFO)

“First-in, first-out” is a crucial aspect of inventory management. It implies your most seasoned or aged, stock (first-in) should be the first one that gets sold (first-out), and not your freshest stock.

This is particularly significant for perishable items so you don’t wind up with unsellable waste.

It’s likewise a smart idea to practice FIFO for durable items. In the event that the same boxes are perpetually lying at the back of your warehouse, they’re bound to expire at some point.

In addition to this, the packaging and product features can (and should), evolve over time. You would obviously prefer not to be left with something outdated that you can’t sell.

Your distribution centers need to be organised in order to implement a FIFO framework.

This ordinarily means including new items from the back, or generally ensuring old item remains at the front. In case you’re working with a warehousing organization they most likely do this already, but it’s never a bad idea to call them and affirm.

Regular auditing

Routine audits are crucial. By and large, you’ll be depending on the warehousing software and reports from your distribution center to know how many items you have stock. Be that as it may, it’s still imperative to ensure the numbers coincide. There are a few techniques for doing this.

- Physical inventory

Doing physical stock means checking all your stock in a single go. Numerous organizations do this at their year-end since it coincides with bookkeeping and documenting annual assessments.

Even though physical inventories are done just once every year, it can practically put business to a halt, and trust me, it’s dull work. On the off chance that you do discover any inconsistencies, it may be hard to pinpoint the issue when you’ve got a whole year’s worth of books to look through.

- Spot checking

In case you do a full physical inventory check toward the year’s end, and you regularly keep running into issues, or you have a ton of items to keep track of, you might need to perform spot-checking on a more consistent basis.

This basically means picking an item, checking it, and checking whether the number is what it should be. This isn’t done on a calendar and is supplemental to physical stock. Specifically, you might need to spot check items that move quickly through the production line to delivery.

- Cycle counting

Rather than performing a complete physical inventory, a few organizations choose to apply cycle checking when reviewing their stock.

As opposed to a full tally at year-end, cycle checking spreads checking throughout the calendar. Every day, week, or month an alternate item is checked. There are various strategies for figuring out which things to tally when, in any case, as a rule, products which have a higher value will be tallied more often.

Prioritize with ABC

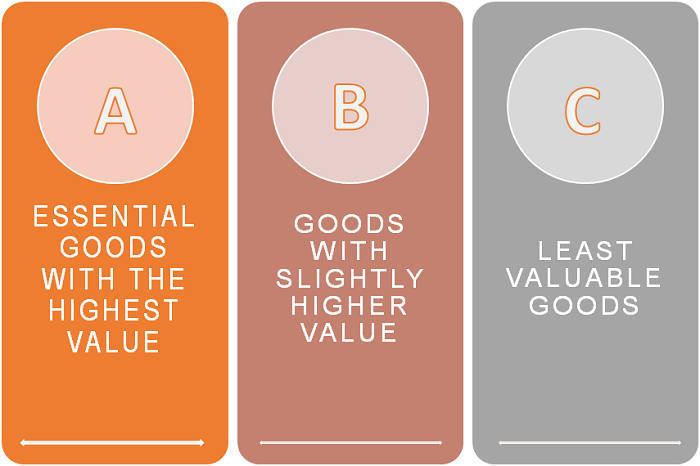

Certain items need more consideration than others. Utilizing an ABC framework enables you to organize your task by isolating items that require more tending to from those that need less. Do this by categorizing your items into one of three classes:

High-value, low sales frequency – Category A

Moderate worth items with a moderate recurrence of sales – Category B

Low-value, high sales frequency items – Category C

As the financial impact of category A items are more significant but the occurrence of a sale is unpredictable, they require more frequent tending to. You can get away with paying slightly less attention to category C items as they have a higher sales frequency and they are less financially significant. Category B items are somewhere in between.

Take control of your inventory with the help Syncoria’s ERP modules. Syncoria is a Toronto based, full-service digital agency.

Odoo is our ready partner, and we have provided custom solutions and system integration services to customers across a wide range of industries.

With the use of the Odoo ERP modules, we provide customized solutions to transform and optimize your business process. Our local team consists of business analysts, solutions architects, project managers, delivery managers, and quality assurance engineers, all of whom are trained experts in Odoo.

We ensure we reach successful implementation every time through an iterative and transparent process. For a free assessment, call us at +1 (416) 628-5522, or email us at [email protected].