Related Articles

Stock administration is a significant part of a business’ productivity, yet a large number of SMBs don’t practice good inventory management with regards to the things they sell.

As you scale, it’s normal to forget about what stock you have and where it is located. Since most brands begin inventory management on spreadsheets, stock systems are exceedingly manual and take a considerable amount of time.

Efficient, innovative, and powerful stock administration methods are essential as you scale.

It is only natural that having too little stock is harmful for a business. Clients end up becoming frustrated when the things they’re searching for aren’t physically available on your shelf or through your site.

Probably a portion of those clients will go somewhere else for the missing item. The potential hazard this poses is that customers who leave and find the item elsewhere, may never look back.

A few organizations go the other way, however, and overload things “in the event that something goes wrong.” While you’re certain to have the things your clients are searching for, the risk that this strategy poses is draining cash from your business. In addition to tying up a significant amount of your income, the excess inventories also costs more to store and track.

The perfect solution to your inventory management is somewhere in between the aforementioned extremes. When you achieve an efficient management process, your effort will be reflected in your profits.

What is Inventory Management?

Before we go into a discussion about some efficient inventory management techniques, let us first define what inventory management is.

Inventory management is the process of following your stock from when it’s manufactured all the way through to fulfillment.

There are numerous techniques of inventory management that helps your company work with more efficiency while allowing you better visibility and control. Basically, inventory management comprises of the business applications that oversee inventory for you.

Stock control is definitely more vigorous than the old-school spreadsheet framework. As a rule, you can screen how much stock you have at some random time over the entirety of your business channels while using reporting capabilities that gives you valuable insight into your business and clients.

Why is Inventory Management important?

It can be annoying to implement a whole new inventory control system because of the amount of time and effort it takes. It’s easier and more tempting to get other things sorted, like your marketing.

It can however, be worthwhile to have firm control over your inventory management, as it may be hugely beneficial to your company:

- Increased sales: Better inventory management means you won’t lose out on sales, as customers won’t turn to competitors to order items that you have run out of stock.

- Loyal customers: Inventory control helps create loyalty. Studies show 65% customers don’t look back on a brand after a single bad experience.

- Reduced storage costs: With the right amount of stock on hand at any one time means you don’t have to pay for any unnecessary storage.

- Less waste: Inventory that sits in your warehouse for too long, especially perishable goods, will lead to a waste of all sorts of resources.

All of this means you have more cash in the bank that can be invested in growth and expansion.

A good inventory management system improves cash flow in more ways than one. Your inventory is products that you have already paid for, and plan to sell, but it’s practically worthless while it remains in your warehouse. You can’t pay rent with anything but cash.

It’s therefore important to factor in inventory into your cash flow management as inventory directly relates to sales, expenses, and both of these heavily influence how much cash you have on you at any one time. Essentially, better inventory management leads to better cash flow management as well.

With a sound inventory system you’ll know exactly how much product you have, be able to project when you might run out based on sales and know when you have to reorder. This not only ensures that you don’t lose sales (when you run out of stock of a product and do not reorder on time), it also lets you stay one step ahead for buying more.

Now let us dive into some tried and tested inventory management techniques that are sure to cut down your costs in the long run. This list is quite extensive and beyond the scope of this blog, therefore we will only be focusing on some of the best techniques out there.

Tried and tested inventory management techniques

The optimal inventory management system can be different for each company, as it is a highly customizable part of doing business.

Every business should however, make an effort to reduce, if not remove, human error from inventory management as much as possible. There are great and powerful inventory management software out there which can help you do this.

Regardless of which system you use, the following techniques will definitely help you improve your inventory management, as well as cash flow.

1. Set par levels

Setting “par levels” for your products make inventory management much easier. This is basically the minimum amount of any product that you need at all times. When your stock drops below these levels, you’ll know to order more.

Par levels are varied based on the product in question and how long it takes to get it back in stock. Even though setting par levels initially involves some amount of research and decision making, it will bring order to your orders (pun shamelessly intended). This will not only make it easier for you to make decisions, but it will also allow your staff to make decisions for you.

It is important to remember that the market conditions are prone to change. Par levels need to be checked a few times a year to make sure they are still logical. When conditions do change, you need to adjust your par levels accordingly.

Here is a simple formula for determining a good reorder point for an item:

2. Setting a safety stock level

The safety or backup stock is basically what you keep on-hand for each of your items, in case you run out.

This is for your emergency preparedness, and should not be used for your normal sales. Your safety stock should be kept in reserve in case of sudden increase in demand.

It’s important to make use of as much data available from the past as possible as using an estimate and hoping for the best isn’t ideal.

What we suggest you do is take your best sales days over the past quarter or year and put it into the following formula:

This gives you a better, data-backed estimation for your safety stock.

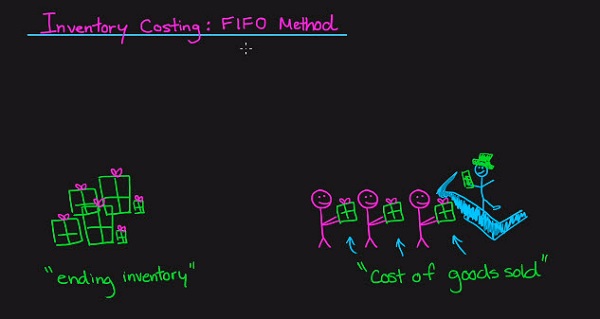

3. First-In First-Out (FIFO)

An important concept of inventory management is “First-in, first-out.” Simply put, your oldest stock (first-in) gets sold first (first-out), every time. This is especially applicable for perishable goods that might become spoilt if left in your warehouse for too long.

Using FIFO for non-perishable goods is also a good idea. Items can get worn out if they’re always sitting at the back of your warehouse. Moreover, packaging, designs, even features, can change overtime and you don’t want to end up with items which are obsolete.

An organized warehouse is need in order to manage a FIFO system. You can do this by adding new products from the back, or ensuring old product stays in the front. Enforcing a rule to store new inventory from the back while taking from the front automatically applies a FIFO system.

4. ABC Prioritization

All your products won’t require the same level of attention, or as often. Prioritizing your inventory using an ABC analysis lets you separate products according to the aforementioned criteria. You can do this by listing your products into one of three categories:

- A Items: high value with low sales frequency.

- B Items: moderate value with moderate sales frequency.

- C Items: low value with high sales frequency.

Items in category A require the most attention because they have a significant financial impact but their sales are unpredictable. Category C items require less oversight since their financial impact is smaller and they are constantly being sold, and items in category B are somewhere in-between.

5. Economic Order Quantity (EOQ)

Having a safety stock and reorder point are useful inventory control methods that can help you figure out when to order new stock. How much to order, however, is a whole different ball game altogether.

You can calculate this using the Economic Order Quantity, which also helps to keep minimum carrying costs.

The three variables EOQ is based on are:

- Demand- The number of units sold over a given time period, usually a year.

- Relevant ordering cost- This equates to the total ordering cost per purchase, and it includes any staff, transportation, and any other cost that comes with making each order.

- Relevant carrying cost- For this you have to assume you have the item in stock for the whole time period in question and figure out the carrying cost per unit.

Once you have all of the above, put them into the following formula:

This equation can seem daunting at first glance, so let’s take a look at an example of how it’s applied.

Imagine your business is selling shoes and you have a demand of 18,000 units per year(1,500 a month). You have also calculated that staffing and transportation gives a total ordering cost of £75 per purchase order while carrying costs is at £4 per unit.

Putting these values into the formula gives us:

Economic Order Quantity = square root of [((2 x 18,000) x £75) ÷ £4]

Economic Order Quantity = square root of [2,700,000 ÷ £4]

Economic Order Quantity = square root of 675,000

Economic Order Quantity = 822

Based on our calculations above, the perfect order quantity for this specific item would be 822 units per order.

6. Regular auditing

Regular reconciliation ensures you stay on top of your inventory. Most companies depend on software and reports to keep track of how much product is in stock. It is important however, to make sure the facts match up. There are several methods for doing this:

Physical inventory

A physical stock is the practice of checking all your stock at one go. Numerous organizations do this at the end of their accounting period since it ties in with bookkeeping and filing taxes. Even though physical inventories are commonly just done once every year, it tends to disturb the normal operations of a business, and trust me, it’s difficult.

On the off chance that you do discover a disparity, it may very well be hard to pinpoint the issue when you’re glancing back at a whole year.

Spot checking

On the off chance that you complete a full physical stock toward the year’s end and you regularly keep running into issues, or you have a great deal of items, you might need to begin spot checking consistently.

This just means picking an item, checking it, and comparing it to the number it should be. This isn’t done according to a schedule and is supplemental to physical inventory. Specifically, you might need to spot check risky or fast moving items.

Cycle counting

Rather than completing a full physical inventory, a few organizations use cycle tallying to review their stock. As opposed to a full check at year-end, cycle tallying spreads out the process throughout the year. Every day, week, or month an alternate item is checked based on a cycling schedule.

There are distinctive techniques for figuring out which items to count when, but generally, as a rule, highly valued inventory is counted more often.

7. Inventory reporting

Inventory management tools often produce helpful reports based off of the information that you provide. These reports can give valuable insight into your stock, warehouse(s), buying, advertising, and buyer conduct.

For example, Target was able to see how its physical locations were transforming into satisfaction centers: of all of their online sales in 2015, 15% were in-store pick-ups.

By differentiating inventory under specific categories, brands can better understand which items are moving, how it is moving in different areas, and much more. Investigating these reports can help brands make educated buying decisions later on.

While you’re at it, making your suppliers aware of the patterns you see with respect to your stock can enable them to plan appropriately. It is critical for your brand to give your suppliers appropriate notice of what’s required and when, as they are your partners after all.

It’s important to make use of the information you get from your stock control techniques. 25% of retailers face issues with inventory management techniques that they ascribe to the absence of proper communication of information all throughout the organization.

Appropriate detailing will likewise enable you to ascertain reorder amounts and set low-stock limits. This guarantees that you have the precise amount of stock.

8. Using minimal stock level

“Minimal stock is the minimal amount of safety inventory you are willing to keep on hand before replenishing your supplies. This quantity is never static and should be adjusted when needed.

For instance, with a seasonal business like skis, bikes and home improvements, adjustments in stock levels are made based on the time of year. Making adjustments ensures that you never run into stock-outs during your peak seasons. In your low seasons, holding fewer inventory items will free up your cash flow.

Businesses that use perishable goods will also want to use minimal stock as a control. Set your minimum and maximum levels to be the same. This lowers your risk of carrying dead stock if it is not used in time.

More monitoring is required for using minimal stock as a control measure. By carrying less volume, you will need to increase the frequency of your replenishment. In the end, this may not save you any money since you may be incurring more shipping charges.” – Colleen Rodericks,Inventory Management Techniques and Best Practices, inFlow.

Analytics which are up to date will allow you to optimize your business operations and make educated decisions. Nowadays, cloud-based inventory management systems can give you a clear insight into your inventory– whenever, wherever.

In order to run a successful business, you have to have access to critical information as soon as it is available. Brands need to be able to make decisions quickly, and remain adaptable in their operations in order to stay competitive.

9. Bundling

Determining what to order and when can be very troublesome, especially without inventory management techniques. In some cases, you end up purchasing too much of an item, even when you have taken measures to avoid it.

There are inventory management techniques that can help you deal with aging inventory. Bundling is often used by companies as a promotional strategy to move aging inventory.

You can bundle effectively by:

- Giving your customers a free gift with their orders will not only serve to please them, but it can help get rid of aging inventory. In the event that you keep the free item a mystery, you can switch it up based on what is available. This can help you avoid having to forecast a future demand for the item, and customers will feel special when they believe that the offer is exclusive.

- When you bundle an item along with your order at reduced prices, customers will feel as if they are getting a good deal, and you’re not heavily discounting the item. As a result, the customer believes they are getting a bargain, and you are moving aging inventory.

10. Vendor-Managed Inventory

“As the name implies, vendor-managed inventory (VMI) is inventory that is managed by the supplier (also called dropshipping). And while there can be more to it than this, at a minimum this means the vendor determines when to replenish and how much to replenish.

“Vendor-managed inventory is nothing new; in fact it’s been around a long time and is far more common than you may think. If you ever worked in a restaurant, you would have seen the “bread guy” show up every day or so, check your inventory (physically look at your breads, buns, etc.), then go out to his truck and stock you up.

In a barbershop, many of the hair products your barber (yeah I’m old school, I go to a barber) sells or uses are also managed by the supplier. In this case, it’s probably the sales rep for that product that actually “manages” the inventory, and he may restock the barbershop from the trunk of his car.

At the old independent hardware store, items like nuts, bolts, washers, o-rings, etc. were often managed by the vendor. In larger businesses, you may have your shipping cartons, office supplies, or cleaning/maintenance supplies managed by the vendor.” – Dave Piasecki, Vendor-Managed Inventory (VMI): What is it and When Does It Make Sense to Use It, InventoryOps.com

Outsourcing is very nearly a perfect situation from an inventory management viewpoint. Rather than conveying stock and shipping items yourself, the manufacturer or distributor deals with it for you. This basically eliminates inventory management from your business.

Many wholesalers and manufacturers offer drop shipping and advertise it as a service, but don’t worry even if your supplier doesn’t. It might still be an option if you communicate your ideas to them. The increase in cost of products when compared to bulk orders is counteracted by reduced expenses relating to keeping inventory and storage.

How inventory management can help your business

Even though you may have inventory management tools and techniques in place already, it might behoove you to find an optimal inventory management solution which fits your current operations.

With a progressively coordinated and connected back-end, you’ll have significantly more knowledge of your business and more checkpoints to guarantee precision and recognize disparities.

You could likewise take the opportunity to reassess alternate tools and check whether they have every one of the capacities you have to develop your business, or in the event that you ought to move to something different.

A goal of inventory management is to make it less demanding to gather noteworthy information from data, rather than displaying crude numbers in a spreadsheet from which you need to make inferences and recognize patterns yourself.

Finding the perfect method to control your stock can be difficult as your brand scales, and driving multichannel growth is crucial.

The most critical part of stock control is to computerize tedious and error-prone tasks and match up stock over numerous business channels, so your brand always has its best sellers in stock. Delayed purchases and unfulfilled orders can easily be avoided by centralizing your inventory.

When you’ve decided on the techniques to attempt, you must examine them. Research assumes a vital role in helping you figure out what works or what doesn’t for your specific brand.

So far, we have discussed several inventory and warehouse management techniques, why they are important, and how they can help your business perform as efficiently as possible. Now let us look at an inventory management software that can help you do most, if not all, of the above.

Odoo

Odoo is a modern online warehouse management software. It is designed to help you maximize your warehouse efficiency. Below are some of the features of Odoo’s inventory management software that are advertised on their website:

- Organize your warehouse better with the intelligent double entry inventory system.

- Odoo boasts a fully automated replenishment system– using order points and automated Request for Quotations (RFQ’s), it increases the efficiency of your supply chain.

- Advanced stocking procedures are made easy to understand

- Drop-shipping

- Cross-docking

- Multi-warehouse

You will be able to track every stock move, from purchase to sales order with Odoo’s unique double-entry inventory system. Odoo gives you total traceability over serials upstream or downstream from your supply chain.

-

Clear and complete reporting

Real-time dynamic reports that you can share quickly help you keep up to date and make smarter decisions. You can also customize your dashboard to keep key information at your fingertips at all times.

-

Fully integrated with Odoo Apps

Sales

Automatically update your stock levels and forecast quantities based on quotations and sales orders.

Purchase

Automate RFQs and POs based on minimum stock or sales orders and keep track of incoming shipments.

Accounting

Skip the data entry. Odoo Inventory is fully integrated with Odoo Accounting, so stock movements hit your books in real time.

Let us now look at the case of CSC Scientific, and how switching to Odoo helped them save thousands of dollars.

How CSC Scientific Saved $25,000 per Year by Switching from Netsuite to Odoo: A case study

First, a little bit of background on CSC Scientific, as provided on the Odoo website:

For over 100 years, CSC Scientific has been in the business of manufacturing and distributing laboratory equipment. The company specifically specializes in test instrumentation for Moisture Determination, Particle Size Distribution and Liquid Properties Analysis applications.

CSC Scientific designs and manufactures approximately a half of the items they distribute. The remaining items are handled on a resale basis for gaps in the company’s coverage of applications.

The type of users that benefit most from the company’s instrumentation are quality control, product development, and production personnel at industrial companies. The industries that are covered by CSC Scientific include Food Processing, Agriculture, Chemical Production, Pharmaceutical/Cosmetics, Power Generation, and Petroleum, and they would also include Laboratory Supply dealers.

CSC Scientific is based in Fairfax, Virginia, where they also have a sister company, Scientific Gear, which operates as a laboratory equipment distributor and technical service provider. Both companies have switched from Netsuite to Odoo, as they realized that Odoo could offer them a comparable solution that would fulfill all their business needs for a significantly lower price.

The story of CSC Scientific Company dates back to 1889, when a pharmacist in Chicago needed new instruments and production equipment. He had designed his own but was unable to find manufacturers willing to produce it in anything but large quantities. The pharmacist decided he would have them manufactured in any case and then sell the excess – that was the beginning of CSC Scientific Company.

A Pricey Long-Lasting Relationship with Netsuite

CSC Scientific has come a long way since the pharmacist in Chicago. It’s a well established and successful company that has been in existence for over a century, producing and selling industrial instruments and equipment.

For several years, and up until April 2016, CSC Scientific had been using Netsuite to cover all of its business functions. However, when the company discovered that Odoo was able to promise better functionality at a much lower price than Netsuite, it seemed like an obvious choice.

CSC Scientific said they were immediately attracted to Odoo by the promise of a modern solution for about a fifth of the cost of Netsuite. In addition, they had not been entirely content with the interface that Netsuite had to offer, and were looking for something newer with a more flexible workflow.

“I would not hesitate to recommend Odoo as a good responsive set of applications, nor would I hesitate to suggest a switch from Netsuite to Odoo“

Art Gatenby, President of CSC Scientific Company, Inc.

Painless Switch with a Shallow Learning Curve

CSC Scientific was approaching a point when they had to renew their Netsuite subscription, and they knew that it would be difficult to negotiate the price down to the amount they wanted to pay.

They were already convinced that Odoo was a cheaper option to Netsuite, but what they were looking to do was to recreate their current workflow with a flexible solution like Odoo. The company implemented the same apps that they were using with Netsuite, with the addition of a few new ones from Odoo.

Currently they’re using Odoo Sales, Accounting, Invoicing, Inventory, Purchasing, Manufacturing, Inventory, Website and eCommerce, with two extra integrations; FedEx and UPS.

After the expected implementation time, plus a few weeks of giving the team enough time to learn the new procedures, CSC Scientific had already arrived to a point where they had accomplished the desired functionality with Odoo. Additionally, they had achieved the expected cost saving of $25,000 a year that had been promised to them by Odoo.

A Powerful Solution with a Supportive Consultant Results in a Satisfied Client

Since the implementation of Odoo, things have been going smoothly for CSC Scientific. The functionality and features they have are comparable to what they had before, although their workflow is now much more flexible and they’re happy with their new, user-friendly interface.

But in addition to the fulfillment of the company’s operational business needs, CSC Scientific was very pleased with the responsiveness of the Odoo team and their eagerness to help with any problems that emerged. The implementation, from the moment when the decision was made to convert to Odoo, until smooth operation was achieved, took less than 4 months.

CSC Scientific stands by the Odoo apps and system, and they found their Odoo project coordinator, Stephanie Kolb, to be a valuable asset during this time. The initial hook however, for CSC Scientific to switch over to Odoo, was the financial aspect and cutting costs, and since the implementation they have managed to cut costs by $25,000 per year.

Now let us look at the case of Florida Iron Doors, and how a team of Odoo’s most dedicated consultants helped them implement their ideal business solution.

How a Dedicated Team of Odoo Consultants Helped Florida Iron Doors Implement their Ideal Business Solution: A case study

First, a little bit about Florida Iron Doors:

Florida Iron Doors really became a serious player in the Iron Doors Industry when they passed the Miame Dade Hurricane testing and the water infiltration test, but their real game changer came in 2016. That year, Home Depot accepted Florida Iron Doors as one of its three Iron Door vendors. This was a huge deal as Home Depot is the largest Home Improvement Retailer in the United States with net sales of $94 billion for the fiscal year 2016.

Florida Iron Doors is a relatively young company created in 2013. With a background in construction, the company has a unique perspective that shows in each of their custom doors. From front entry doors to exterior French doors, their handcrafted doors can be made to each customer’s satisfaction.

A System Unable to Keep up with Sales Increase

Since Florida Iron Doors was created it immediately took off. This growth was already impressive and getting difficult to manage with their old management system.

In 2016, when they also landed the deal of a lifetime with Home Depot, and opened a new 20,000 SF facility allowing them to increase production even further, something had to change. Prior to Odoo, the company was using several different non-integrated software systems and spreadsheets to manage their operations. With their rapid growth, this system soon began to cause them problems;

Customer data had to be entered into multiple systems, which created data integrity problems.

They were using several spreadsheets to manage their CRM. Without a proper CRM system that could manage leads and the sales pipeline, the sales follow-up process was difficult to handle.

The Inventory software they were using was not integrated with the Sales Software, which meant that all information between the two had to be managed manually. This created inefficiency in daily processes and increased the likelihood of data inaccuracy.

There was a vast disconnection between the Sales Department, the Warehouse and the Delivery Team. This combined with the fact that they were using spreadsheets to manage deliveries, was creating critical errors in servicing their customers needs.

Third Time’s the Charm – Odoo Online Saves the Day

Business was booming and Florida Iron Doors was expecting even further growth following the Home Depot sales. With a more elaborate and complex business, Florida Iron Doors found that it was in need of a powerful integrated system that could handle all business processes throughout the company.

They felt that Odoo was a good fit for them, and began looking into the different options available. They tried Odoo 8 Community Version, and Odoo 10 Enterprise Version. They wanted to host Odoo on their own server and customize it themselves with their own developers.

However, in the end their in-house developers did not have the level of knowledge of Odoo to implement and customize the solution to the standards they’d hoped. Eventually, Florida Iron Doors decided that going with Odoo Online was the right decision for them.

They decided that the safest and best decision would be to purchase a Success Pack with the implementation. This way they could have Odoo technical and functional consultants guide them through the process. They finally managed to get the solution that they needed, and the improvements that they wanted;

With the fully integrated solution they wanted, the days of data accuracy issues were behind them. Now they have a complete information flow.

With Odoo CRM they could now easily follow up with their customers as the CRM system allows them to build and manage their pipelines.

With the integration between Odoo Sales and Odoo Inventory, all transfer of information from the Sales Team to the Warehouse Team had been streamlined. This increased the overall efficiency, and in combination with Odoo CRM this has also greatly improved their end customers experience.

They now have an integrated flow, from keeping track of leads, prospects and customers with the Odoo CRM, to managing quotations and invoices with Odoo Sales and Odoo Invoicing, managing their stock levels with Odoo Inventory, and their finances with Odoo Accounting.

“Our account manager, Igor Cardoso, has been absolutely critical to the success of this project. He not only takes the time to understand our needs, he actively searches for solutions.

He has given me his 200% every time I have reached out. I feel as if he is a real partner in this implementation. The rest of the Odoo Team is stellar. From the speed and efficiency of our functional consultant, Stephanie, to the developers to the tech support staff. Odoo has established a culture of excellence within their team.” -Operations & Strategy Manager at Florida Iron Doors.

A Culture of Excellence Brings out the Best in Florida Iron Doors

After having decided to move to Odoo Online and taking the additional Success Pack, It has been an amazing experience for Florida Iron Doors.

They are very happy with the excellent customer service, and the assistance and support of their Account Manager, Igor, and Functional Consultant, Stephanie. With Odoo Online and the Odoo team, they were able to accomplish in a mere 8 weeks, what they had been unable to accomplish in a year and a half with Odoo Community and Odoo 10 Enterprise.

Once everything settled with the Odoo Online solution implemented, Florida Iron Doors is thrilled with their flexible, out-of-the-box solution, which they only made a few minor customizations to. Overall they felt they’d received a high quality solution, with outstanding customer service for a reasonable price.

Whether you’re looking for an inventory management software or any other business solution, Odoo’s got you covered. The best part about Odoo is that you can customize the apps that you only need and reduce unnecessary expenses on fixed packages. Feel free to try a demo on our website or contact us through email to find out how we can help you grow your business.