Related Articles

MRP modules for spare parts inventory managemnet. More often than not parts distribution centers and spare parts inventories don’t get the consideration they need to guarantee that they work proficiently and stay precise. A few reasons we see this are that the management sees the spare parts department don’t produce much revenue for the organization and they conclude that the spare parts inventory shouldn’t be something that is difficult to oversee.

It is exactly this outlook, alongside neglecting to deal with your parts systematically and neglecting to use the well accepted best practices of the distribution center, or the best MRP modules for the job, can be hazardous. On the off chance that the center ever has to turn its attention to solve these problems, you will quickly realise that it can be quite troublesome and agonizing.

7 MRP Modules For Spare Parts Inventory Management

Luckily, there are things that should be possible that will help guarantee that issues don’t emerge in the first place, and ensure the smooth operation of your parts distribution center. A definitive framework for spare parts inventory ensures that the parts division continues to be increasingly proactive and receptive to the plant. Organizations can save a significant amount of money by identifying parts and spare parts that are already in their warehouse rather than exporting it from abroad. Here are seven spare parts inventory management best practices for overseeing parts stock all the more viably:

1. Identify all parts using a system

When your machinery will be down and in need for a significant upgrade, there might be a few things that are bought for a one-time use. Due to this, some of these parts may not be registered as a stock item and will not show up when you search for it in the inventory management system. Once the machinery has been repaired/upgraded, there might be unused parts which might serve a purpose in the future and ought to be stocked and registered. Other pieces of machinery in the plant might be able to utilize these unused parts. Instead of having these parts put away in a crate, a storeroom, or a warehouse where it will never be opened, they ought to be added to the stock control framework and set into spare parts stock.

2. Make use of and Manage the Bill of Materials (BOM)

BOMs will make requesting new parts and putting in purchase orders a lot less difficult. Also, you have to make sure that your BOMs are constantly updated. It would be terrible if you begin to make errors in counting stock due to a part or multiple parts not being included, updated, or expelled from a BOM.

Furthermore, having an accurate and up to date BOM will likewise help you with pre-booked preventive maintenance (PM) that is required on a particular piece of machinery. Certain frameworks have the added feature of generating a work order on the scheduled preventive maintenance date.

3. Optimize and streamline the work order process

Have a solid work order process, but also make it simple and straightforward enough so that everyone can follow it. Work orders should be designed with all parts in mind with the goal that stock stays precise. Build up a work request process that isn’t excessively convoluted, yet guarantees that all vital data is passed along. On the off chance that it is excessively complicated or there are approaches to get parts without a work request, you will discover employees not utilizing the ideal procedure and error pertaining to inventory start to happen.

Have a system where work orders which are not an emergency are put ahead of time. Work orders which are placed ahead of time can be pulled and arranged for pickup or conveyed to their respective department. This will lessen the pressure and wait time on the maintenance division at the parts distribution center for their work request to be satisfied.

4. Implement security measures

Adequate safety measures must be taken in the spare parts warehouse. A few basic practices should be considered. Restricting access to the parts distribution center stock is essential to keeping up the accuracy of the inventory. Implement a system such that only warehouse workers have access to the parts inventory, and the rest are forbidden to enter.

The primary method to achieve this would be to apply physical safety efforts, for example, parts counters that keep workers from entering stock areas and pulling parts as required. Permitting everybody to approach can rapidly make parts inventories wrong.

The subsequent practice to help aid this goal would be to introduce surveillance cameras and use preventive access to the section for entering and leaving.

5. Centralize and consolidate all parts

Wherever feasible, you must endeavour to bring together and merge spare parts stock into your primary parts distribution warehouse. Having every one of your parts brought together and solidified can make security simpler, not to mention makes this potentially huge resource simpler to navigate, control, and maintain the accuracy of inventory.

6. Make use of the Inventory control system

By using your MRP’s built in utilities or a Warehouse Management System (WMS), – and not spreadsheets – to deal with your spare parts stock will not only guarantee precision and simplicity of dealing with your parts distribution center, but will additionally help to standardize tags and examine the usefulness related to the system. All of this will significantly improve the productivity of your operations in the spare parts warehouse and enhance stock precision.

7. Uniquely locate each part

You must ensure that the stock areas are made using the least amount of detail (normally a container and a separate space for each SKU). It might prove difficult for an employee to find a section if the area code is where numerous other parts are also stored.

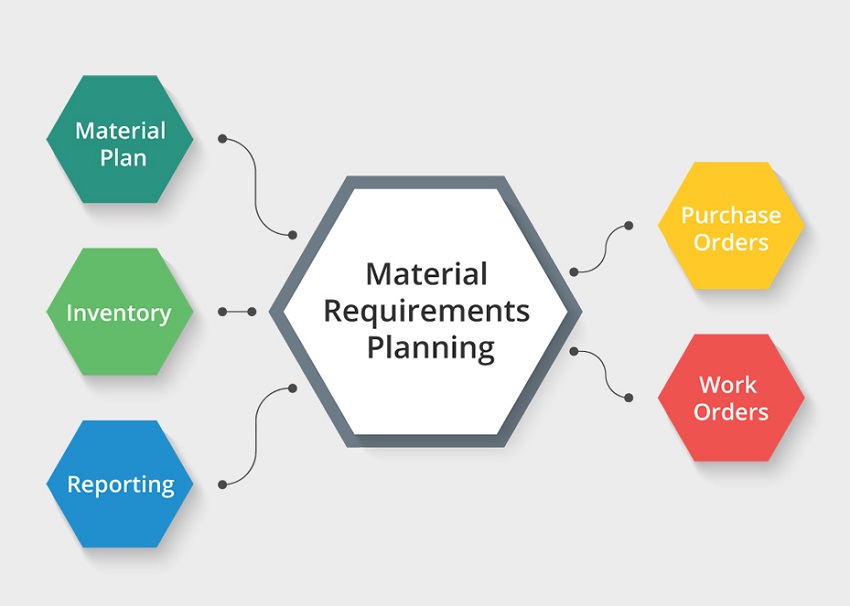

By using the MRP modules for the above suggestions, you will be better able to exercise control over your stock, as well as improve the management of your inventory, and consequently be able to provide quicker and more efficient fulfillment of purchase orders and easily find spare parts when you need them. An MRP will have all the built in features and functionalities that will help you optimize your operations.

We at Syncoria have the experience of working with businesses large and small alike. Our tailored solutions are designed to your exact specifications, based on your own unique needs, and help you achieve your business goals. Through the use of Odoo’s many intuitive modules, we provide customized solutions to transform and optimize your business processes. Our local team consists of business analysts, solution architects, project managers, delivery managers, and quality assurance engineers, all of whom are trained experts in Odoo. We ensure we reach successful implementation every time through an iterative and transparent process. For a free assessment, call us at +1 (416) 628-5522, or email us at odoo@syncoria.com.