Related Articles

Odoo quality control in manufacturing.

Every manufacturer sees quality management as a primary objective.

Trouble is, many businesses are not doing it the right way – or worse, doing it completely the wrong way.

For instance, many businesses still rely on paper-based methods for quality control inspection, analysis, and monitoring. Other businesses still rely on manual processes to do the same thing.

In today’s day and age of advanced technologies, such archaic processes are an operational minefield waiting to explode.

Supply chains and legal and compliance prerequisites are growing more complex by the day, and manual processes just aren’t going to cut it in such a fast-paced environment. After all, manual processes do not only take oodles and oodles of time – they are also prone for show-stopping errors.

Granted, there are plenty of legacy software that many companies still rely on to help them deal with their quality control requirements – but we all know that they can no longer cut the mustard as far as modern quality standards are concerned.

The manufacturing disciplines, standards, and practices today are not only complex, but they are driven primarily by quality. This is mirrored by the fact that enterprise resource planning (ERP) systems are created for this purpose, particularly for ERP platforms that involve quality control processes.

While it is understandable that people should believe that ERP solutions must always include quality control processes as a logical part of its evolution, the truth is that it varies from platform to platform. That is, quality control features will differ with regards to usability and and practicality depending on the ERP system that is implemented. Much of it has to deal with 1) the price, and 2) the operational scale of the chosen system.

As a result, it is imperative for business owners – manufacturers, in particular – to know what to look for in an ERP system for quality control, what they mean for small to medium-sized process manufacturers, and why we think Odoo should be included as one of the top choices in the market today.

Why is quality control critical for manufacturers?

We can’t get to the meat of the matter without understanding a few principles regarding enterprise resource planning for manufacturing.

It must further be mentioned that there is a substantial difference between enterprise resource planning for process manufacturing against discreet manufacturing. This is because both types of manufacturing have different and corresponding levels of quality control.

However, it must be noted that regardless of a company’s manufacturing type, the final business goal for each type is to create a finished product after integrating an array of sub-elements.

Here’s the thing: whereas active quality validation through a certain production chain is what ERP-driven process manufacturing involves, discreet manufacturing works differently.

Companies engaged in discreet manufacturing typically buy production sub-components based on baseline quality, which had already been inspected by a third-party supply chain provider.

Process manufacturing, on the other hand, deals directly with manufacturing recipes and formulas. This is a key difference from discreet manufacturers who assemble pre-validated subcomponents to create a finished product, which makes process manufacturing a little more challenging with regard to dealing with quality control.

Take, for instance, the manufacturing of medicines and pharmaceuticals. Such products require constant quality control every step of the way given the fact that the final product is created through a wide array of chemical subprocesses and synthetic components that come with an expiration date, among other things.

Missing out on a process step or not being able to verify it for quality can mean that an entire production run is lost – to the tune of thousands of dollars.

Worse, this can lead to even more legal and reputational risks that do not end at the loss of money, but worse, the loss of lives from ill patients who need the product.

That said, let’s take a look at three important quality control features that you should be looking for in an enterprise resource planning solution.

3 crucial quality control functions your chosen ERP solution should have

We’ve come up with three important quality control features that organizations seeking to implement an ERP QC system should have.

Here they are as follows.

1. Ideally, your ERP quality control solution should be able to issue instructions regarding procedures, track events, adequately measure them, and then save the results that are related to it. Remember the old quality control adage: if it isn’t documented, then it never occurred in the first place. Therefore, the ability to distinguish and take account of all steps starting from the procurement of raw materials to the finished product is an absolutely critical function that ERP quality control for companies engaged in process manufacturing.

2. You’ll want to guarantee your chosen quality control system can determine, define, and implement an active priority method for the manufacturing processes your company undertakes. This suggestion is particularly applicable to substrates, compounds, and chemicals that are used in the process of creating pharmaceutical-based products. In the event that regulatory or compliance investigation is undertaken for any reason, such capability will serve a support mechanism to do so.

3. Lastly, you’ll want to ensure that your chosen quality control system can implement active rules and enforce internal policies. This is because compliance is standard operating procedure for today’s standards of process manufacturing. The same is true for your chosen ERP quality management apps or modules. All these factors need to be responsive to today’s standards across city, state, national, and/or international norms. Such compliance should be implemented all throughout the development and actual production of any manufacturing recipe that may in the end eventually be sold for public consumption.

Clearly, these three best practices are but a small portion of the requirements you need to implement a bulletproof ERP quality control solution, but these are the factors (along the lines of similar analogous factors) are what you’ll want to focus on.

We think Odoo’s enterprise resource planning platform is an excellent solution for manufacturers seeking to carry out, tighten up, and optimize their quality control processes.

Enter Odoo Quality Control Management

Odoo Quality Control Management is a fantastic QC management ERP solution that provides a foundational infrastructure for production lot quality testing. It allows you to do so through the use of checkpoints located in the supply chain.

You will be able to create, manage, and monitor quality control plans through it. We at Syncoria can help you integrate quality control modules with your existing warehouse management and inventory modules.

However, before we take a look at the quality control module in detail, let’s look at the reason why it was developed in the first place.

Odoo’s Quality Control Management module guarantees that the quality of any product you manufactured is at your highest standard, while ensuring that its distribution is successful the first time, every time. And, to do this, you need to generate quality control points that will include the overall implementation of your quality control plan.

Let’s take a look at how Odoo Quality Control Management helps manufacturing companies achieve their quality control management systems.

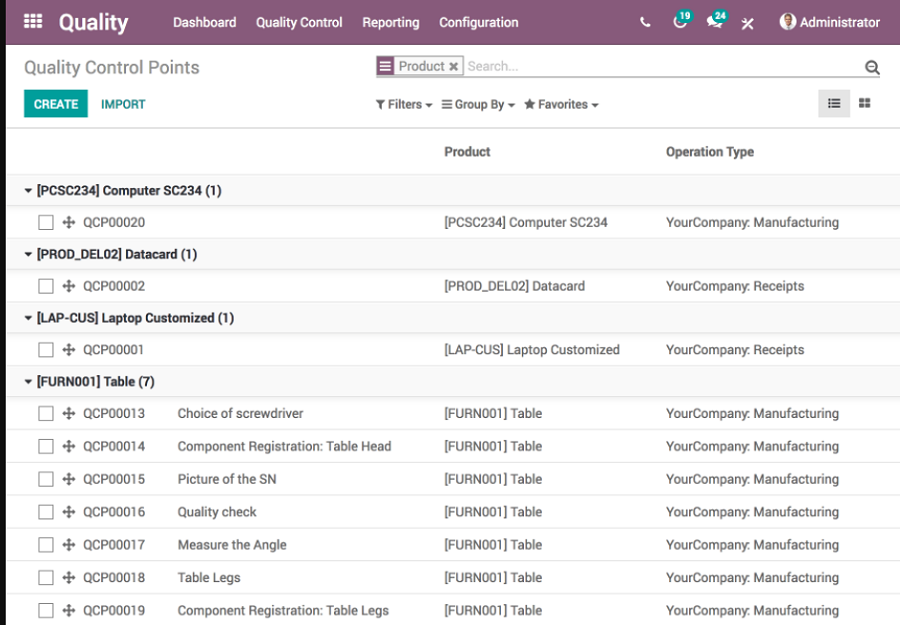

Quality Control Points

- Set up multiple quality control plans to set off quality control checks at designated inventory operations (such as receiving and final quality control inspection) or manufacturing operations by way of in-process quality control operations).

- Define inspections based on quality control plans.

- Oversee and monitor production part approval process submissions and configure statistical process control parameters. Lastly, you can put up the process failure mode and effects analysis each time you route.

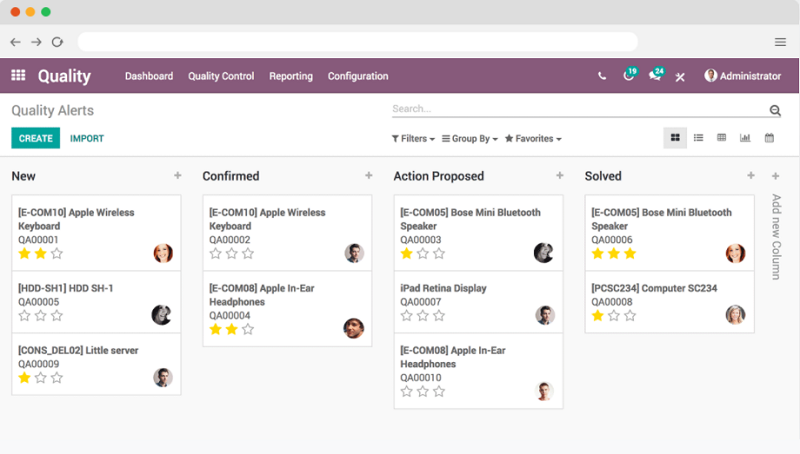

Keep track of quality alerts with a clean, intuitive interface

- Organize quality alerts with Odoo’s intuitive user interface.

- Quickly drag and drop alerts to monitor your manufacturing progress and utilize useful visual indicators to keep track of important alerts.

- Easily organize quality alerts and implement rules to automate actions or alerts. You can categorize either by requestor, addressee, and so many more ways.

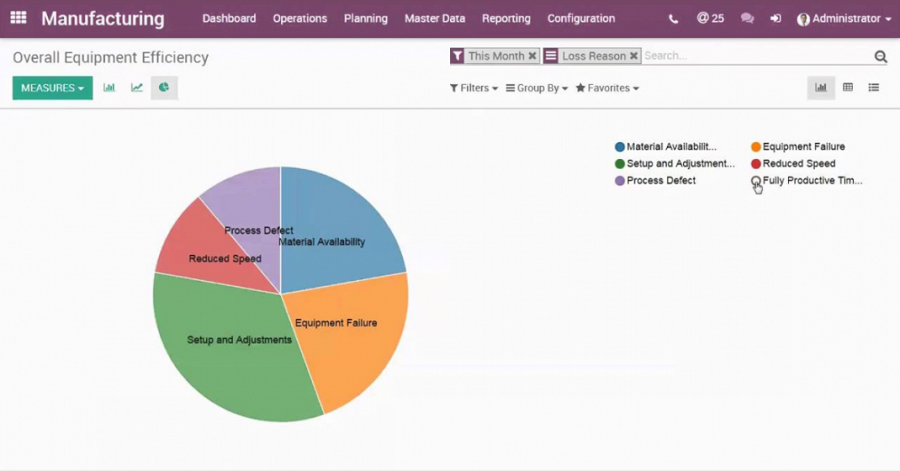

Improve overall quality with comprehensive productive maintenance.

- Your organization’s manufacturing department can set off quality alerts straight from the control panel. Odoo works such that every time a requested is updated, the correct recipients receive the correct information in real time.

- Improved communication reduces manufacturing downtime and boosts operational efficiency.

Quality Inspection during Manufacturing

This module is available in Odoo. It allows you to generate production quality control reports regardless of what production stage you are currently in. Configure as many reports as you need on any number of existing work orders you might have.

You also get the benefit of tracking product, production order, work order, control point, as well as production lot number with easily visible failed parameters, among many other things. Lastly, you can also check against your current parameters with information on maximum and minimum tolerance.

This feature is critical to check real-time production progress at any stage and monitor its quality simultaneously. And it’s all created in a simple Excel spreadsheet!

Conclusion

Quality control is essential for companies engaged in any form of manufacturing due to reasons that are already apparent to us. Not performing quality control is not an option for any manufacturing company worth its salt, no matter what their size may be.

Odoo Quality Control Management is a fantastic open source ERP solution module that can be easily integrated with data sources and mobile or desktop devices to help set up quality control points throughout the manufacturing lifecycle.

This ensures that your products are not only up to your company’s high standards of quality, but also to be able to pass with increasingly complex legal and compliance standards that change quite literally by the day. Odoo might just be the perfect solution for your small to medium-sized company due to its inherent flexibility and innovative modular approach. It doesn’t matter what you manufacture – Odoo has thousands of modules at your perusal, each guaranteed to suit your company’s requirements. Contact us now to see how we can find the best way to harness the power of Odoo and have it reflect on your bottom line today!